In the manufacturing industry, robots have slowly been taking over the tasks typically done by human workers. But what happens when you combine the strengths of both robots and humans? Cobots, or collaborative robots, are designed to work with human employees to achieve goals beyond what either could do alone. In this article, we’ll explore the benefits of cobots and find out how they’re changing the manufacturing landscape. Stay tuned.

What Are Cobots, And How Do They Work?

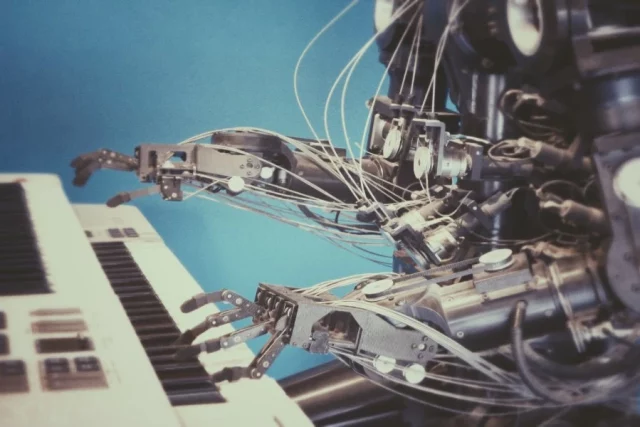

Cobots, or collaborative robots, are an increasingly popular technology in the workplace. Unlike regular robots, cobots are designed for human interaction and work directly alongside people. They utilize advanced sensors and computer vision to monitor their surroundings and decide how best to complete a task.

By working together with humans, cobots help to increase productivity and worker safety; by constantly adapting to their environment, they can avoid potentially dangerous situations requiring humans to take action manually. Overall, cobots are a broadly helpful technology that can help businesses leverage the full potential of their workforce.

The Benefits Of Using Cobots

There are many reasons why cobots are becoming increasingly popular in the manufacturing sector. First and foremost, they can help to increase productivity by working alongside human employees to complete tasks more efficiently. In addition, cobots can improve worker safety by constantly monitoring their surroundings and taking action to avoid potential hazards.

Furthermore, cobots are highly versatile and can be used in various industries beyond manufacturing. For example, they are also being utilized in healthcare settings to assist nurses and doctors with patient care.

How Humans And Cobots Can Work Together

Now that we know a bit about cobots and their benefits let’s take a closer look at how humans and cobots can work together to achieve better results. One of the key advantages of using cobots is that they can help businesses to optimize their workflow. By working with human employees, cobots can help businesses identify bottlenecks and improve overall efficiency.

In addition, cobots can also help businesses to save money by reducing the need for manual labor. In many cases, cobots can do tasks traditionally done by human workers, such as assembly line work or packaging. As a result, businesses can reduce labor costs by investing in cobots instead of hiring additional staff.

Finally, it’s important to note that cobots can help businesses to improve their customer service. By working with human employees, cobots can help businesses provide a higher level of service and support. Customers often prefer dealing with cobots over humans because they are faster and more efficient. As a result, businesses that use cobots can often improve their customer satisfaction levels.

Examples Of Successful Cobot/Human Collaborations

Let’s have a look at some examples of this collaboration.

ABB and BMW

ABB, a leading robotics manufacturer, has worked with BMW for over 25 years to provide cobots for their production lines. Together, they have developed various cobot applications, including factory automation, body shop operations, and assembly line tasks.

KUKA and Daimler

KUKA, another leading robotics manufacturer, has been working with Daimler since 2006 to develop cobots for automotive assembly lines. Together, they have created many cobot applications, including welding, painting, and screwing.

FANUC and Toyota

FANUC, the world’s largest robotics manufacturer, has been working with Toyota since the 1980s to provide cobots for their production lines. Together, they developed various cobot applications, including material handling, assembly, and welding.

Yaskawa and Nissan

Yaskawa, the world’s largest robotics manufacturer, has been working with Nissan since 2002 to provide cobots for their production lines. Together, they developed various cobot applications, including painting, welding, and assembly.

The Future Of Cobots And Human Interaction

As you can see, there are already many successful examples of cobots and humans working together. In the future, we will likely see even more businesses investing in this technology. As cobots become more advanced, they can take on more complex tasks and work in even more diverse environments.

As businesses become more aware of the benefits of using cobots, we will likely see wider adoption of this technology. In the future, cobots may become an essential part of many businesses, just like computers and other office equipment are today.

The Bottom Line

Cobots offer many advantages for businesses, including increased productivity, improved worker safety, and lower labor costs. In addition, they can also help businesses to optimize their workflow and improve their customer service. If you’re looking for a way to give your business a competitive edge, then investing in cobots is undoubtedly worth considering.