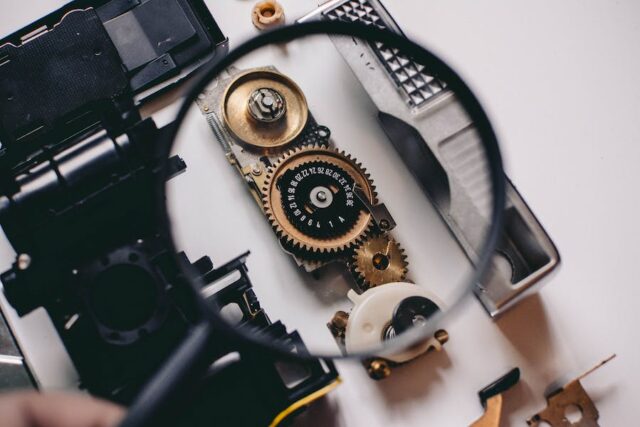

In the realm of advanced machinery, precision gearing stands out as a crucial component that drives efficiency and accuracy. As a reader navigating the intricate landscape of modern technology, you understand the pivotal role that gearing plays in ensuring seamless operations. Here are some of the distinctive features that set precision gearing apart, shedding light on the advancements that elevate it to a league of its own.

Unrivaled Accuracy

Precision gearing is synonymous with unparalleled accuracy. Precision gearing, unlike conventional gear systems, utilizes cutting-edge technologies and manufacturing processes to achieve exceptionally tight tolerances. Personalized solutions from Nabtesco Motion Control can revolutionize your machinery, elevating it to new heights of precision, efficiency, and adaptability. This precision is essential in applications where even the slightest deviation can lead to significant errors. As you delve into the intricacies of advanced machinery, you’ll appreciate how this accuracy enhances the overall performance and reliability of the system.

Superior Durability And Longevity

When it comes to the longevity of machinery, precision gearing takes the lead. The materials and manufacturing methods employed in crafting precision gears result in components that can withstand extreme conditions and heavy loads. This level of durability not only minimizes maintenance requirements but also ensures a longer lifespan for the machinery. As you seek reliability in your industrial endeavors, precision gearing proves to be a steadfast companion, capable of enduring the rigors of demanding applications.

Enhanced Efficiency And Energy Savings

Efficiency is paramount in the world of advanced machinery, and precision gearing is designed to optimize it to the fullest. The meticulous engineering of these gears minimizes friction, leading to smoother operations and reduced energy consumption.

In your pursuit of efficiency gains, precision gearing emerges as a key player in achieving sustainable and cost-effective machinery performance. The ability to extract maximum output with minimal energy input aligns seamlessly with the contemporary emphasis on eco-friendly and resource-efficient industrial practices.

Tailored Solutions For Varied Applications

One size does not fit all, especially in the diverse landscape of advanced machinery applications. Precision gearing stands out by offering tailored solutions to meet the specific requirements of different industries. Whether it’s aerospace, automotive, or robotics, precision gearing can be customized to address unique challenges. This adaptability ensures that your machinery operates at its optimal capacity, regardless of the sector you find yourself in.

Material Selection

Precision gearing allows for the selection of materials tailored to the specific demands of an industry. Whether it’s lightweight and corrosion-resistant alloys for aerospace applications or high-strength materials for heavy-duty industrial machinery, the ability to choose the right materials ensures optimal performance in diverse environments.

Custom Gear Configurations

In addition to material customization, precision gearing offers flexibility in gear configurations. Different industries may require specific gear ratios, tooth profiles, or gearing arrangements to meet their unique operational needs. Precision gearing allows for the customization of these parameters, ensuring that the machinery is finely tuned to deliver maximum efficiency in its intended application.

Temperature and Environmental Adaptability

Precision gearing can be designed to withstand extreme temperature variations and environmental conditions. This adaptability is crucial in industries such as automotive manufacturing, where machinery operates in diverse climates, or in the oil and gas sector, where equipment must endure harsh environmental elements. Customizing precision gears for temperature and environmental resilience ensures consistent performance in challenging settings.

Minimal Noise And Vibration

Precision gearing introduces a significant advancement in reducing noise and vibration levels within machinery. Traditional gear systems often generate considerable noise, contributing to both operational discomfort and potential wear and tear.

In contrast, the meticulous design and manufacturing of precision gears focus on minimizing these undesirable effects. As you integrate precision gearing into your machinery, you’ll experience a quieter and smoother operational environment, ensuring a more pleasant workplace and extended equipment life.

High Torque Transmission

When it comes to transmitting torque in advanced machinery, precision gearing excels in delivering exceptional performance. The design intricacies of precision gears allow for the efficient transfer of high levels of torque, which is crucial in applications where heavy loads or sudden accelerations are common.

This characteristic not only enhances the overall power transmission efficiency but also opens doors for using smaller, more compact machinery in various industrial settings, optimizing both space and functionality.

Digital Integration For Smart Manufacturing

In the era of Industry 4.0, where smart manufacturing is the norm, precision gearing seamlessly integrates with digital technologies. These gears can be equipped with sensors and connectivity features, providing real-time data on performance metrics. As you embrace digital transformation in your industrial processes, precision gearing becomes a cornerstone in enabling predictive maintenance, data-driven decision-making, and overall operational intelligence, contributing to a more efficient and future-ready manufacturing environment.

Sensor Technology

Precision gearing integrates seamlessly with sensor technologies, allowing for the incorporation of various sensors such as temperature sensors, vibration sensors, and load sensors directly into the gear system. These sensors provide real-time data, offering insights into the operating conditions and health of the machinery. The utilization of sensor technology enhances the overall monitoring capabilities, enabling early detection of potential issues and facilitating predictive maintenance strategies.

Connectivity Solutions

Precision gearing supports connectivity features that enable data transmission and communication within the manufacturing ecosystem. Through IoT (Internet of Things) connectivity, these gears can communicate with other components of the machinery, control systems, and even cloud-based platforms. This interconnectedness enhances collaboration and coordination among different elements, contributing to a more synchronized and responsive manufacturing environment.

Cost-Effective Production

While precision gearing may be associated with cutting-edge technology, it also brings cost-effectiveness to the table. The durability and reliability of precision gears lead to reduced downtime and maintenance costs, translating into long-term financial savings. Moreover, the enhanced efficiency and energy savings contribute to a more economical operation over the life cycle of the machinery. As you weigh the investment in precision gearing, the long-term cost benefits become a compelling factor in favor of this advanced technology.

From minimizing noise and vibration to facilitating high torque transmission, from seamless digital integration to offering cost-effective production solutions, precision gearing proves its versatility and indispensability. As you navigate the complexities of modern industrial applications, consider precision gearing not just as a component but as a transformative force, propelling your machinery towards unprecedented levels of performance, reliability, and innovation.